The Stretch Tutorials reposotory provides tutorials on programming the Stretch RE1 and RE2 robots. The tutorials are organized into the following tracks.

The Stretch Tutorials repository provides tutorials on programming Stretch robots. The tutorials are organized into the following tracks.

The Stretch RE1 or RE2 comes with a set of command line tools that are helpful for introspection during general use or while troubleshooting issues. This page provides an overview of these tools. If you like, visit the [stretch_body](https://github.com/hello-robot/stretch_body/tree/master/tools/bin) repository to have a look under the hood.

The Stretch robot comes with a set of command line tools that are helpful for introspection during general use or while troubleshooting issues. This page provides an overview of these tools. If you like, visit the [stretch_body](https://github.com/hello-robot/stretch_body/tree/master/tools/bin) repository to have a look under the hood.

You can execute these commands from anywhere in the terminal. We recommend you to execute these commands as we follow each one of them. You can also find the description for the utility each tool provides by passing the optional '-h' flag along with the tool name in the terminal. For example, from anywhere in the terminal execute:

Congratulations on your Stretch RE2! This guide will get you started with your new robot.

Congratulations on your Stretch 2! This guide will get you started with your new robot.

## Safety

@ -8,7 +8,7 @@ Stretch has the potential to cause harm if not properly used. All users should r

## Unboxing

Please watch the [Stretch Unboxing Video](https://youtu.be/O-6VrqqGlig).

Please watch the [Stretch Unboxing Video](https://youtu.be/O-6VrqqGlig). Please note that the unboxing instructions for a Stretch 2 are the same as for a Stretch RE1.

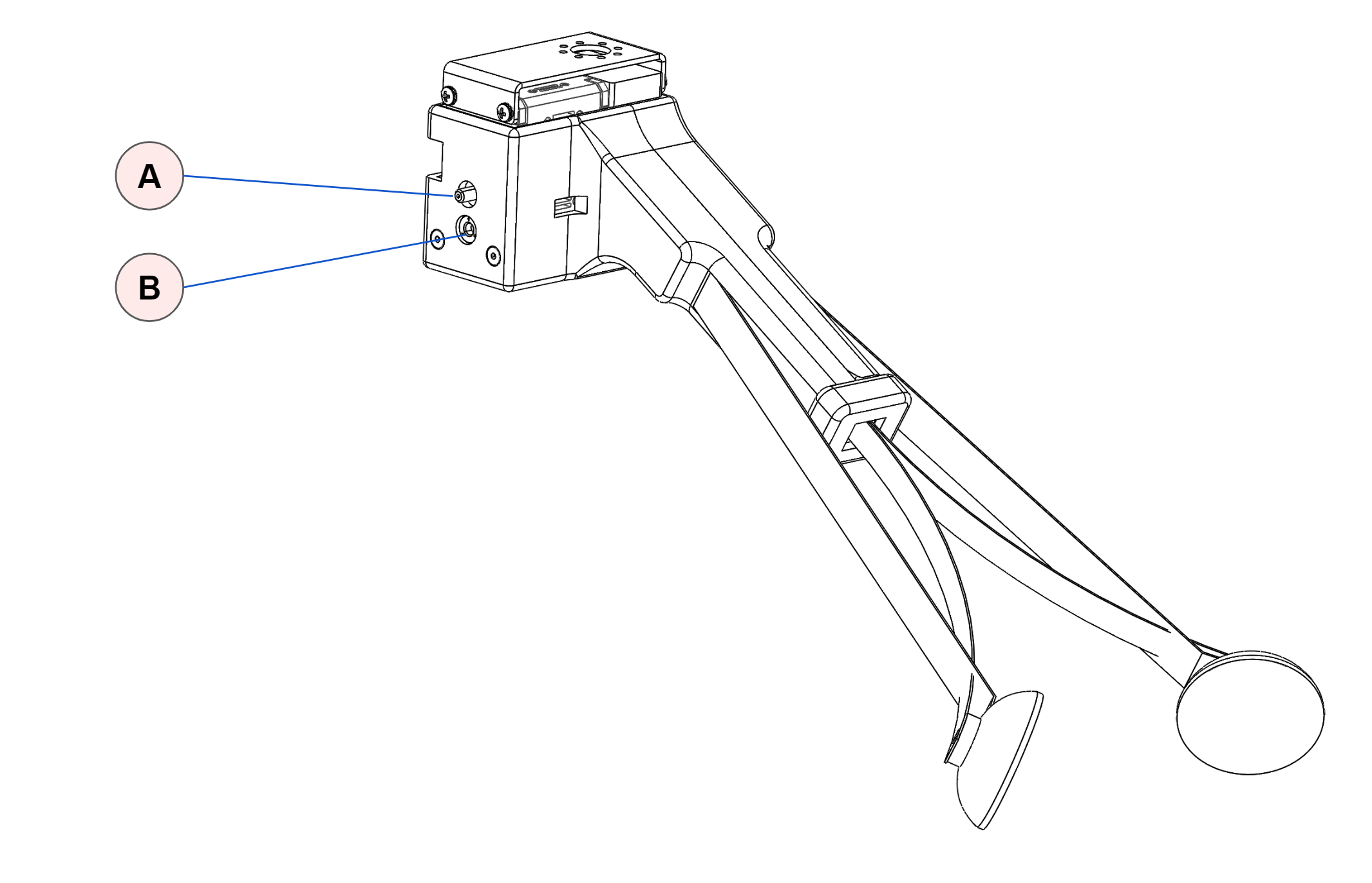

## Robot Tour

@ -77,14 +77,14 @@ If you're done, let's power down. First attach the clip-clamp just below the sho

Hold down the Shutdown PC button on the Xbox controller for 2 seconds. This will cause the PC to turn off. You can then power down the robot with the On/Off switch.

Now that you're familiar with the robot, take a minute to watch the [Stretch Powered Best Practices Video](https://youtu.be/iEaapHNfEWA).

Now that you're familiar with the robot, take a minute to watch the [Stretch Powered Best Practices Video](https://youtu.be/iEaapHNfEWA). Please note that the best practices instructions for a Stretch 2 are the same as for a Stretch RE1.

### Safe Handling

Like any robot, it is possible to break Stretch if you're not careful. Use common sense when applying forces to its joints, transporting it, etc.

The [Stretch Unpowered Best Practices Video](https://youtu.be/mQdOGEksdYM) provides a quick overview of how to work with the robot.

The [Stretch Unpowered Best Practices Video](https://youtu.be/mQdOGEksdYM) provides a quick overview of how to work with the robot. Please note that the best practices instructions for a Stretch 2 are the same as for a Stretch RE1.

**Things that won't hurt the robot**:

@ -98,7 +98,7 @@ The [Stretch Unpowered Best Practices Video](https://youtu.be/mQdOGEksdYM) provi

* Manually moving the head and wrist. They will move but they want to go at their own speed.

* The lift will slowly descend when the robot is powered off. If the arm is retracted it may come to rest the tool on the base. If desired to hold the arm up when un-powered, the provided 'clip-clamp' can be clipped onto the mast below the shoulder to support it.

**NOTE**: The RE2 lift descends faster than the RE1. For the RE2 we recommend always attaching the clip-clamp prior to powering down the NUC computer

**NOTE**: The Stretch 2 lift descends faster than the Stretch RE1. For Stretch 2 we recommend always attaching the clip-clamp prior to powering down the NUC computer

The Stretch RE1 and RE2 are potentially dangerous machine with safety hazards. **If improperly used it can cause injury or death.**

The Stretch robots are potentially dangerous machines with safety hazards. **If improperly used they can cause injury or death.**

* **All users must carefully read the following safety information prior to using the robot.**

* Anyone near the robot who has not read this safety information must be closely supervised at all times and made aware that the robot could be dangerous.

@ -10,7 +10,7 @@ The Stretch RE1 and RE2 are potentially dangerous machine with safety hazards. *

## Intended Use

**The Stretch RE1/RE2 (“Stretch”) are intended for use by researchers to conduct research in controlled indoor environments.** This product is not intended for other uses and lacks the required certifications for other uses, such as use in the home by consumers.

**The Stretch robots are intended for use by researchers to conduct research in controlled indoor environments.** This product is not intended for other uses and lacks the required certifications for other uses, such as use in a home environment by consumers.

## Safety Hazards

@ -172,7 +172,7 @@ The runstop logic is:

### Sharp Edges

Stretch RE1/RE2 is a piece of laboratory equipment. As such, its structure has moderately sharp edges and corners that can be unsafe. These edges can get snagged during motion, or they may cause lacerations when sufficient force is applied to a person. Care should be taken when grasping or otherwise making contact with Stretch that a sharp corner or edge is not contacted.

The Stretch robot is a piece of laboratory equipment. As such, its structure has moderately sharp edges and corners that can be unsafe. These edges can get snagged during motion, or they may cause lacerations when sufficient force is applied to a person. Care should be taken when grasping or otherwise making contact with Stretch that a sharp corner or edge is not contacted.

@ -23,9 +23,9 @@ In addition, check that the provided USB dongle is plugged into the robot USB po

Please review the troubleshooting section of the [RE1 Battery Maintenance Guide](https://docs.hello-robot.com/0.2/stretch-hardware-guides/battery_maintenance_guide_re1/).

=== "Stretch RE2"

=== "Stretch 2"

Please review the troubleshooting section of the [RE2 Battery Maintenance Guide](https://docs.hello-robot.com/0.2/stretch-hardware-guides/battery_maintenance_guide_re2).

Please review the troubleshooting section of the [Stretch 2 Battery Maintenance Guide](https://docs.hello-robot.com/0.2/stretch-hardware-guides/battery_maintenance_guide_re2).

## RPC Transport Errors (Stretch doesn't respond to commands)

Despite the name, ROS is not an operating system. ROS is a middleware framework that is a collection of transport protocols, development and debugging tools, and open-source packages. As a transport protocol, ROS enables distributed communication via messages between nodes. As a development and debugging toolkit, ROS provides build systems that allows for writing applications in a wide variety of languages (Python and C++ are used in this tutorial track), a launch system to manage the execution of mutiple nodes simultaneously, and command line tools to interact with the running system. Finally, as a popular ecosystem, there are many open-source ROS packages that allow users to quickly prototype with new sensors, actuators, planners, perception stacks, and more.

This tutorial track is for users looking to become familiar with programming the Stretch RE1 and RE2 via ROS Noetic. We recommend going through the tutorials in the following order:

This tutorial track is for users looking to get familiar with programming Stretch robots via ROS. We recommend going through the tutorials in the following order:

stretch_navigation provides the standard ROS navigation stack as two launch files. This package utilizes gmapping, move_base, and AMCL to drive Stretch around a mapped space. Running this code will require the robot to be untethered.

stretch_navigation provides the standard ROS navigation stack as two launch files. This package utilizes gmapping, move_base, and AMCL to drive Stretch around a mapped space. Running this code will require the robot to be [untethered](https://docs.hello-robot.com/0.2/stretch-tutorials/getting_started/untethered_operation/).

Then run the following commands to map the space that the robot will navigate in.

@ -7,7 +7,7 @@ NOTE: Stretch's ROS2 packages and this ROS2 tutorial track are both under active

Despite the name, ROS is not an operating system. ROS is a middleware framework that is a collection of transport protocols, development and debugging tools, and open-source packages. As a transport protocol, ROS enables distributed communication via messages between nodes. As a development and debugging toolkit, ROS provides build systems that allows for writing applications in a wide variety of languages (Python and C++ are used in this tutorial track), a launch system to manage the execution of mutiple nodes simultaneously, and command line tools to interact with the running system. Finally, as a popular ecosystem, there are many open-source ROS packages that allow users to quickly prototype with new sensors, actuators, planners, perception stacks, and more.

This tutorial track is for users looking to become familiar with programming the Stretch RE1 and RE2 via ROS 2. We recommend going through the tutorials in the following order:

This tutorial track is for users looking to get familiar with programming Stretch robots via ROS 2. We recommend going through the tutorials in the following order:

[Stretch Body](https://github.com/hello-robot/stretch_body) is a set of Python packages that allow a developer to directly program the hardware of the Stretch RE1 and RE2 robots. The Stretch Body interface is intended for users who choose to not use ROS.

[Stretch Body](https://github.com/hello-robot/stretch_body) is a set of Python packages that allow a developer to directly program the hardware of the Stretch robots. The Stretch Body interface is intended for users who are looking for an alternative to ROS.

Stretch Body currently supports both Python2 and Python3. These tutorials assume a general familiarity with Python as well as basic robot motion control.

In this tutorial we will discuss the simple collision avoidance system that runs as a part of Stretch Body.

In this tutorial, we will discuss the simple collision avoidance system that runs as a part of Stretch Body.

## Overview

Stretch Body includes a system to prevent inadvertent self-collisions. It will dynamically limit the range of motion of each joint in order to prevent self-collisions.

Stretch Body includes a system to prevent inadvertent self-collisions. It will dynamically limit the range of motion of each joint to prevent self-collisions.

**NOTE**: Self collisions are still possible while using the collision-avoidance system. The factory default collision models are coarse and not necessarily complete.

!!! warning

Self collisions are still possible while using the collision-avoidance system. The factory default collision models are coarse and not necessarily complete.

This system is turned off by default starting with RE2. It may be turned off by default on many RE1 systems. First check if the collision detection system is turned on:

This system is turned off by default starting with Stretch 2. It may be turned off by default on many RE1 systems. First check if the collision detection system is turned on:

If it is turned off you can enable it by adding the following to your stretch_user_yaml.py

If it is turned off you can enable it by adding the following to your stretch_user_yaml.py:

```bash

robot:

@ -24,24 +25,24 @@ robot:

## Common Self Collisions

Fortunately the simple kinematics of Stretch make self collisions fairly uncommon and simple to predict. The primary places where self collisions may occur are

Fortunately, the simple kinematics of Stretch make self-collisions fairly uncommon and simple to predict. The primary places where self-collisions may occur are

* The lift lowering the wrist or tool into the base

* The arm retracting the wrist or tool into the base

* The head_pan at `pos==0` and head_tilt at `pos=-90 deg` and the lift raising the arm into the camera (minor collision)

* The DexWrist (if installed) and colliding with itself

* The DexWrist (if installed) and colliding with the base

* The DexWrist (if installed) colliding with itself

* The DexWrist (if installed) colliding with the base

## Joint Limits

The collision avoidance system works by dynamically modifying the acceptable range of motion for each joint. By default, a joint's range is set to the physical hardstop limits. For example, the lift has a mechanical throw of 1.1m:

The collision avoidance system works by dynamically modifying the acceptable range of motion for each joint. By default, a joint's range is set to the physical hardstop limits. For example, the lift has a mechanical throw of 1.1m:

A reduced range-of-motion can be set at run-time by setting the Soft Motion Limit. For example, to limit the lift range of motion to 0.3 meter off the base:

A reduced range of motion can be set at run-time by setting the Soft Motion Limit. For example, to limit the lift range of motion to 0.3 meters off the base:

```python

import stretch_body.robot as robot

@ -50,9 +51,9 @@ r.startup()

r.lift.set_soft_motion_limit_min(0.3)

```

We see in the [API](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/lift.py), the value of `None` is used to designated no soft limit.

We see in the [API](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/lift.py), the value of `None` is used to designate no soft limit.

It is possible that when setting the Soft Motion Limit that the joint's current position is outside of the specified range. In this case, the joint will move to the nearest soft limit so as to comply with the limits. This can be demonstrated by:

It is possible that when setting the Soft Motion Limit the joint's current position is outside of the specified range. In this case, the joint will move to the nearest soft limit to comply with the limits. This can be demonstrated by:

The [RobotCollision](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision.py) class manages a set of [RobotCollisionModels](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision.py). Each [RobotCollisionModel](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision.py) computes the soft limits for a subset of joints based on a simple geometric model. This geometric model captures the enumerated set of potential collisions listed above.

We can see the which collision models will execute when `use_collision_manager` is set to 1:

We can see which collision models will execute when `use_collision_manager` is set to 1:

We see two models. One that protects the camera from the arm, and one that protects the base from the gripper. Each model is registered with the [RobotCollision](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision.py) instance as a loadable plug-in. The [Robot](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot.py) class calls the `RobotCollision.step` method periodically at approximately 10hz.

`RobotCollision.step`computes the 'AND' of the limits specified across each Collision Model such that the most restrictive joint limits are set for each joint using the `set_soft_motion_limit_min , set_soft_motion_limt_max` methods.

`RobotCollision.step` computes the 'AND' of the limits specified across each Collision Model such that the most restrictive joint limits are set for each joint using the `set_soft_motion_limit_min` and `set_soft_motion_limt_max` methods.

## Default Collision Models

The default collision models for Stretch Body are found in [robot_collision_models.py](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision_models.py). As of this writing, the provide models are:

The default collision models for Stretch Body are found in [robot_collision_models.py](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision_models.py). As of this writing, the provided models are:

* [CollisionArmCamera](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision_models.py#L8): Avoid collision of the head camera with the arm

* [CollisionStretchGripper](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_collision_models.py#L75): Avoid collision of the wrist-yaw and gripper with the base and ground

**NOTE**: The provided collision models are coarse and are provided to avoid common potentially harmful collisions only. Using these models it is still possible to collide the robot with itself in some cases.

!!! warning

The provided collision models are coarse and are provided to avoid common potentially harmful collisions only. Using these models it is still possible to collide the robot with itself in some cases.

**NOTE**: Additional collision models are provided for the DexWrist

!!! info

Additional collision models are provided for the DexWrist

### Working with Models

The collision models to be used by Stretch Body are defined with the `robot_collision` parameter. For example, we see in `robot_params.py` that the CollisionArmCamera is loaded by default

The collision models to be used by Stretch Body are defined with the `robot_collision` parameter. For example, we see in `robot_params.py` that the CollisionArmCamera is loaded by default:

It can be straightforward to create your own custom collision model. As an example, we will create a model that avoids collision of the arm with a tabletop by

It is straightforward to create a custom collision model. As an example, we will create a model that avoids collision of the arm with a tabletop by

* Prevent the lift from descending below the table top when the arm is extended

* Allow the lift to descend below the tabletop so long as the arm retracted

* Preventing the lift from descending below the table top when the arm is extended

* Allowing the lift to descend below the tabletop so long as the arm retracted

This assumes the arm is initially above the tabletop. To start, in a file `collision_arm_table.py` we add:

This assumes the arm is initially above the tabletop. To start, in a file `collision_arm_table.py` we add:

```python

from stretch_body.robot_collision import *

@ -211,16 +214,15 @@ class CollisionArmTable(RobotCollisionModel):

limits['lift']=[table_height+safety_margin,None]

return limits

```

In this example we include the `safety_margin` as a way to introduce some hysteresis around state changes to avoid toggling between the soft limits.

In this example, we include the `safety_margin` as a way to introduce some hysteresis around state changes to avoid toggling between the soft limits.

The following command should be run in order to add the working directory to the PYTHONPATH env , This can also be added to our bashrc to permanently edit the path:

The following command should be run to add the working directory to the PYTHONPATH env. This can also be added to our `.bashrc` to permanently edit the path:

Stretch Body includes the package [hello-robot-stretch-body-tools](https://github.com/hello-robot/stretch_body/tree/master/tools) -- a suite of command line tools that allow direct interaction with hardware subsystems.

Stretch Body includes the package [hello-robot-stretch-body-tools](https://github.com/hello-robot/stretch_body/tree/master/tools) - a suite of command line tools that allow direct interaction with hardware subsystems.

These tools are useful when developing and debugging applications. They also serve as code examples when developing applications for Stretch_Body.

These tools can be found by tab completion of 'stretch_' from a terminal.

These tools can be found by tab completion of 'stretch_' from a terminal.

```console

$ stretch_

@ -45,7 +45,7 @@ stretch_wrist_yaw_jog.py

stretch_xbox_controller_teleop.py

```

All tools accept '--help' as a command line argument to learn its function. For example:

All tools accept the '--help' flag as a command line argument to describe its function. For example:

```console

>>$ stretch_pimu_scope.py --help

@ -78,22 +78,21 @@ optional arguments:

--bump Scope base imu bump level

```

### Commonly Used Tools

## Commonly Used Tools

These are the tools a typical user will want to become familiar with.

These are the tools a typical user is expected to interact with regularly and would benefit from becoming familiar with.

| **stretch_robot_home.py** | Commonly run after booting up the robot in-order to calibrate the joints |

| **stretch_robot_system_check.py** | Scans for all hardware devices and ensure they are present on the bus and reporting valid values. Useful to verify that the robot is in good working order prior to commanding motion. It will report all success in green, failures in red. |

| **stretch_robot_system_check.py** | Scans for all hardware devices and ensures they are present on the bus and reporting valid values. Useful to verify that the robot is in good working order prior to commanding motion. It will report all success in green, failures in red. |

| **stretch_robot_stow.py** | Useful to return the robot arm and tool to a safe position within the base footprint. It can also be useful if a program fails to exit cleanly and the robot joints are not backdriveable. It will restore them to their 'Safety' state. |

| **stretch_robot_battery_check.py** | Quick way to check the battery voltage / current consumption |

| **stretch_xbox_controller_teleop.py** | Useful to quickly test if a robot can achieve a task by manually teleoperating the robot |

| **stretch_robot_dynamixel_reboot.py** | This will reset all Dynamixels in the robot, which may be needed if a servo overheats during high use and enters an error state. |

| **stretch_robot_dynamixel_reboot.py** | Resets all Dynamixels in the robot, which might be necessary if a servo overheats during use and enters an error state. |

Take a minute to explore each of these tools from the console.

------

<divalign="center"> All materials are Copyright 2022 by Hello Robot Inc. Hello Robot and Stretch are registered trademarks.</div>

You should see that the arm stops on contact when it extends, however it doesn't stop on contact when it then retracts. This is the guarded contact behavior in action.

You should see that the arm stops on contact when it extends, however, it doesn't stop on contact when it then retracts. This is the guarded contact behavior in action.

## Specifying Guarded Contacts

@ -49,14 +49,15 @@ The four stepper joints (base, arm, and lift) all support guarded contact settin

In this method you can optionally specify a contact threshold in the positive direction (`contact_thresh_pos`) and the negative direction `contact_thresh_neg`.

In this method, you can optionally specify a contact threshold in the positive and negative direction with `contact_thresh_pos` and `contact_thresh_neg` respectively.

**NOTE**: these optional parameters will default to `None`, in which case the motion will adopt the default settings as defined the robot's parameters

!!! note

These optional parameters will default to `None`, in which case the motion will adopt the default settings as defined by the robot's parameters.

**NOTE**: The parameters `contact_thresh_pos_N` and `contact_thresh_neg_N` are deprecate and no-longer supported.

!!! warning

The parameters `contact_thresh_pos_N` and `contact_thresh_neg_N` are deprecated and no longer supported.

A contact model is simply a function that, given a userspecified contact threshold, computes the motor current at which the motor controller will trigger a guarded contact. The following contact models are currently implemented:

A contact model is simply a function that, given a user-specified contact threshold, computes the motor current at which the motor controller will trigger a guarded contact. The following contact models are currently implemented:

### The Effort-Pct Contact Model

[Effort-Pct](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/prismatic_joint.py) is the default contact model for Stretch RE2. It simply scales the maximum range of motor currents into the range of [-100,100]. Thus, if you desire to have the robot arm extend but stop at 50% of its maximum current, you would write:

[Effort-Pct](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/prismatic_joint.py) is the default contact model for Stretch 2. It simply scales the maximum range of motor currents into the range of [-100,100]. Thus, if you desire to have the robot arm extend but stop at 50% of its maximum current, you would write:

```python

robot.arm.move_by(0.1,contact_thresh_pos=50.0)

```

## Adjusting Contact Behaviors

The default factory settings for contact thresholds are tuned to allow Stretch to move throughout its workspace without triggering false-positive guarded contact events. These settings are the worstcase tuning as they account for the internal disturbances of the Stretch drive-train across its entire workspace.

The default factory settings for contact thresholds are tuned to allow Stretch to move throughout its workspace without triggering false-positive guarded contact events. These settings are the worst-case tuning as they account for the internal disturbances of the Stretch drive-train across its entire workspace.

It is possible to obtain greater contact sensitivity in carefully selected portions of the arm and lift workspace. Users who wish to programmatically adjust contact behaviors can create a simple test script and experiment with different values. For example:

It is possible to obtain greater contact sensitivity in carefully selected portions of the arm and lift workspace. Users who wish to programmatically adjust contact behaviors can create a simple test script and experiment with different values. For example:

```python

#!/usr/bin/env python

@ -109,7 +108,7 @@ robot.stop()

## Guarded Contact with the Base

Guarded contacts are enable by default for the arm and lift as they typically require safe and contact sensitive motion. They are turned off on the base by default as varying surface terrain can product undesired false-positive events.

Guarded contacts are enabled by default for the arm and lift as they typically require safe and contact-sensitive motion. They are turned off on the base by default as varying surface terrain can produce undesired false-positive events.

That being said, guarded contacts can be enabled on the base. They may be useful as a simple bump detector such that the base will stop when it runs into a wall.

The Stretch Factory package provides a tool to allow advanced users to recalibrate the default guarded contact thresholds. This tool can be useful if you've added additional payload to the arm and are experiencing false-positive guarded contact detections.

The tool sweeps the joint through its range-of-motion for `ncycle` iterations. It computes the maximum contact forces in both directions, adds a padding (`contact_thresh_calibration_margin`) to this value, and stores it to the robots Configuration yaml.

The tool sweeps the joint through its range of motion for `n-cycle` iterations. It computes the maximum contact forces in both directions, adds padding, `contact_thresh_calibration_margin`, to this value, and stores it to the robot's configuration YAML.

```bash

>>$ REx_calibrate_guarded_contact.py -h

@ -156,12 +153,8 @@ optional arguments:

-h, --help show this help message and exit

--lift Calibrate the lift joint

--arm Calibrate the arm joint

--ncycle NCYCLE Number of sweeps to run [4]

--ncycle NCYCLE Number of sweeps to run [4]

```

------

<divalign="center"> All materials are Copyright 2022 by Hello Robot Inc. Hello Robot and Stretch are registered trademarks.</div>

In this tutorial we explore how to add additional degrees of freedom to the Stretch wrist.

In this tutorial, we explore how to add additional degrees of freedom to the Stretch wrist.

Stretch exposes a Dynamixel X-Series TTL control bus at the end of its arm. It uses the [Dynamixel XL430-W250](https://emanual.robotis.com/docs/en/dxl/x/xl430-w250/) for the [WristYaw](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/wrist_yaw.py) and the [StretchGripper](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/stretch_gripper.py) degrees of freedom that come standard with the robot.

Stretch exposes a Dynamixel X-Series TTL control bus at the end of its arm. It uses the [Dynamixel XL430-W250](https://emanual.robotis.com/docs/en/dxl/x/xl430-w250/) for the [WristYaw](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/wrist_yaw.py) and the [StretchGripper](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/stretch_gripper.py) that comes standard with the robot.

See the [Hardware User Guide](https://docs.hello-robot.com/0.2/stretch-hardware-guides/docs/hardware_guide_re2/#wrist-tool-plate) to learn how to mechanically attach additional DOFs to the robot.

**Note: Stretch is compatible with [any Dynamixel X Series servo](https://emanual.robotis.com/docs/en/dxl/x/) that utilizes the TTL level Multidrop Bus.**

!!! note

Stretch is compatible with any [Dynamixel X Series servo](https://emanual.robotis.com/docs/en/dxl/x/) that utilizes the TTL level Multidrop Bus.

## Adding a Custom DOF

Adding one or more custom Dynamixel X Series servos to Stretch wrist involves:

* Creating a new class that derives from [DynamixelHelloXL430](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/dynamixel_hello_XL430.py)

* Adding YAML parameters to `stretch_user_params.yaml`that configure the servo as desired

* Adding YAML parameters to `stretch_user_params.yaml`that configure the servo as desired

* Adding YAML parameters to `stretch_user_params.yaml` that tell Stretch to include this class in its EndOfArm list of servos

Let's create a new DOF called MyWristPitch in a file named [my_wrist_pitch.py](./custom_wrist_dof/my_wrist_pitch.py). Place the file somewhere on the $PYTHONPATH.

Let's create a new DOF called MyWristPitch in a file named [my_wrist_pitch.py](./custom_wrist_dof/my_wrist_pitch.py). Place the file somewhere on the $PYTHONPATH.

```python

from stretch_body.dynamixel_hello_XL430 import DynamixelHelloXL430

@ -33,7 +34,7 @@ class MyWristPitch(DynamixelHelloXL430):

self.move_to(self.poses[p],v_r,a_r)

```

Now let's add the tools' parameters to your `stretch_user_params.yaml`in order to configure this servo. You may want to adapt these parameters to your application but the nominal values [found here](./custom_wrist_dof/stretch_user_params.yaml) usually work well. Below we highlight some of the more useful parameters.

Now let's add the tools' parameters to your `stretch_user_params.yaml` to configure this servo. You may want to adapt these parameters to your application but the nominal values [found here](./custom_wrist_dof/stretch_user_params.yaml) usually work well. Below we highlight some of the more useful parameters.

```yaml

my_wrist_pitch:

@ -46,9 +47,9 @@ my_wrist_pitch:

zero_t: 2048 #Position in ticks that corresponds to zero radians

```

For this example we are assuming a single turn joint that doesn't require hardstop based homing. We also assume the servo has the Robotis default ID of 1.

For this example, we are assuming a single-turn joint that doesn't require hard stop-based homing. We also assume the servo has the Robotis default ID of 1.

At this point your MyWristPitch class is ready to use. Plug the servo into the cable leaving the Stretch WristYaw joint. Experiment with the API from iPython

At this point, your MyWristPitch class is ready to use. Plug the servo into the cable leaving the Stretch WristYaw joint. Experiment with the API from iPython

```python

In [1]: import my_wrist_pitch

@ -64,7 +65,7 @@ In [5]: w.pose('tool_up')

In [6]: w.pose('tool_down')

```

Finally, you'll want to make your WristPitch available from `stretch_body.robot` Add the following [YAML](./custom_wrist_dof/stretch_user_params.yaml) to your `stretch_user_params.yaml`

Finally, you'll want to make your WristPitch available from `stretch_body.robot`. Add the following [YAML](./custom_wrist_dof/stretch_user_params.yaml) to your `stretch_user_params.yaml`

```yaml

end_of_arm:

@ -74,7 +75,7 @@ end_of_arm:

py_module_name: wrist_pitch

```

This tells `stretch_body.robot` to manage a wrist_`pitch.WristPitch`instance and add it to the [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) list of tools. Try it from iPython:

This tells `stretch_body.robot` to manage a `wrist_pitch.WristPitch`instance and add it to the [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) list of tools. Try it from iPython:

Typically, users will interact with these devices through either the [Head](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/head.py) or [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) interfaces. This tutorial is for users looking to work directly with the servos from the provided servo tools or through Stretch Body's lowlevel Dynamixel API.

Typically, users will interact with these devices through either the [Head](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/head.py) or the [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) interfaces. This tutorial is for users looking to work directly with the servos from the provided servo tools or through Stretch Body's low-level Dynamixel API.

## Servo Tools

**NOTE**: The servo tools here are part of the [Stretch Factory package](https://github.com/hello-robot/stretch_factory) which is installed as a part of Stretch Body.

!!! note

The servo tools here are part of the [Stretch Factory package](https://github.com/hello-robot/stretch_factory) which is installed as a part of Stretch Body.

### Jogging the Servos

@ -49,7 +49,7 @@ e: enable torque

### Rebooting the Servos

Under high-load conditions the servos may enter an error state to protect themselves from thermal overload. In this case, the red LED on the servo will flash (if visible). In addition, the servo will be unresponsive to motion commands. In this case, allow the overheating servo to cool down and reboot the servos using the `stretch_robot_dynamixel_reboot.py` tool:

Under high-load conditions, the servos may enter an error state to protect themselves from thermal overload. In this case, the red LED on the servo will flash (if visible). In addition, the servo will be unresponsive to motion commands. In this case, allow the overheating servo to cool down and reboot the servos using the `stretch_robot_dynamixel_reboot.py` tool:

```bash

$ stretch_robot_dynamixel_reboot.py

@ -65,10 +65,10 @@ For use with S T R E T C H (TM) RESEARCH EDITION from Hello Robot Inc.

### Identify Servos on the Bus

If it is unclear which servos are on the bus, and at what baud rate, you can use the `REx_dynamixel_id_scan.py` tool. Here we see that the two head servos are at ID 11 and 12 at baud 57600.

If it is unclear which servos are on the bus, and at what baud rate, you can use the `REx_dynamixel_id_scan.py` tool. Here we see that the two head servos are at ID `11` and `12` at baud `57600`.

@ -100,7 +100,7 @@ Scanning bus /dev/hello-dynamixel-head at baud rate 57600

### Setting the Servo Baud Rate

Stretch ships with its Dynamixels servos configured to baudrate=115200. When adding your own servos to the end-of-arm tool, you may want to set the servo baud using the `RE1_dynamixel_set_baud.py` tool. For example:

Stretch ships with its Dynamixel servos configured to `baudrate=115200`. When adding your servos to the end-of-arm tool, you may want to set the servo baud using the `REx_dynamixel_set_baud.py` tool. For example:

@ -110,13 +110,16 @@ Checking servo current baud for 57600

Identified current baud of 57600. Changing baud to 115200

Success at changing baud

```

**Note**: Earlier units of Stretch RE1 may be running Dynamixel servos at baud 57600

!!! note

Earlier units of Stretch RE1 may be running Dynamixel servos at baud 57600.

### Setting the Servo ID

Dynamixel servos come with ID=1 from the factory. When adding your own servos to the end-of-arm tool, you may want to set the servo ID using the `REx_dynamixel_id_change.py` tool. For example:

Dynamixel servos come with `ID=1` from the factory. When adding your servos to the end-of-arm tool, you may want to set the servo ID using the `REx_dynamixel_id_change.py` tool. For example:

**NOTE**: The naming of XL430 is for legacy reasons. These classes will work with all X Series servos.

!!! note

The naming of XL430 is for legacy reasons. These classes will work with all X Series servos.

### DynamixelXChain

DynamixelXChain manages a set of daisy-chained servos on a single bus (for example the head_pan and head_tilt servos). It allows for greater communication bandwidth by doing group read/write over USB.

DynamixelXChain manages a set of daisy-chained servos on a single bus (for example the head_pan and head_tilt servos). It allows for greater communication bandwidth by doing a group read/write over USB.

The [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) class derives from DynamixelXChain in order to provide an extensible interface that supports a user integrating additional DOF to the robot. The tutorial [Adding Custom Wrist DOF](./tutorial_custom_wrist_dof.md) explains how to do this.

The [EndOfArm](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/end_of_arm.py) class derives from DynamixelXChain to provide an extensible interface that supports a user in integrating additional degrees of freedom to the robot. The tutorial [Adding Custom Wrist DoF](./tutorial_custom_wrist_dof.md) explains how to do this.

### DynamixelHelloXL430

DynamixelHelloXL430 provides an interface to servo motion that is consistent with the Stretch Body lift, arm, and base joints. It also manages the servo parameters and calibration. Let's explore this interface further. From iPython let's look at the status message for DynamixelHelloXL430

DynamixelHelloXL430 provides an interface to servo motion that is consistent with the Stretch Body lift, arm, and base joints. It also manages the servo parameters and calibration. Let's explore this interface further. From iPython, let's look at the status message for DynamixelHelloXL430

```bash

import stretch_body.dynamixel_hello_XL430

@ -193,7 +197,7 @@ In addition to `move_to` and `move_by`, the class also implements a splined traj

### DynamixelXL430

DynamixelXL430 provides a thin wrapper to the [Robotis Dynamixel SDK](http://emanual.robotis.com/docs/en/dxl/x/xl430-w250/#control-table). You may chose to interact with the servo at this level as well. For example to jog the head_pan 200 ticks:

DynamixelXL430 provides a thin wrapper to the [Robotis Dynamixel SDK](http://emanual.robotis.com/docs/en/dxl/x/xl430-w250/#control-table). You may choose to interact with the servo at this level as well. For example, to jog the head_pan 200 ticks:

```python

import stretch_body.dynamixel_XL430

import time

@ -208,7 +212,5 @@ time.sleep(2.0)

m.stop()

```

------

<divalign="center"> All materials are Copyright 2022 by Hello Robot Inc. Hello Robot and Stretch are registered trademarks.</div>

The Stretch_Body package provides a lowlevel Python API to the Stretch hardware. The Stretch_Body package is intended for advanced users who prefer to not use ROS to control the robot. It assumes a moderate level of experience programming robot sensors and actuators.

The Stretch_Body package provides a low-level Python API to the Stretch hardware. The Stretch_Body package is intended for advanced users who prefer to not use ROS to control the robot. It assumes a moderate level of experience programming robot sensors and actuators.

The package is available on [Git and installable via Pip](https://github.com/hello-robot/stretch_body).

@ -9,11 +9,11 @@ It encapsulates the:

* Arm

* Lift

* Head actuators

* End-of-arm-actuators

* Wrist board with accelerometer (Wacc)

* End-of-arm-actuators

* Wrist board with accelerometer (Wacc)

* Base power and IMU board (Pimu)

As shown below, the primary programming interface to Stretch Body is the [Robot class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot.py). This class encapsulates the various hardware module classes (e.g. Lift, Arm, etc). Each of these modules then communicate the robot's firmware over USB using various utility classes.

As shown below, the primary programming interface to Stretch Body is the [Robot class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot.py). This class encapsulates the various hardware module classes (e.g. Lift, Arm, etc). Each of these modules then communicates with the robot firmware over USB using various utility classes.

The primary developer interface to Stretch_Body is the [Robot class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot.py). Let's write some code to explore the interface. Launch an interactive Python terminal:

@ -35,7 +33,7 @@ The primary developer interface to Stretch_Body is the [Robot class](https://gi

In [1]:

```

And type in the following:

Then type in the following:

```python linenums="1"

import time

@ -52,7 +50,7 @@ robot.stop()

```

As you can see, this prints all Robot sensor and state data to the console every 250ms.

As you can see, this prints all robot sensors and state data to the console every 250ms.

@ -64,7 +62,7 @@ robot=stretch_body.robot.Robot()

robot.startup()

```

Here we instantiated an instance of our Robot. The call to `startup()` opens the serial ports to the various devices, loads the Robot YAML parameters, and launches a few helper threads.

Here we instantiated an instance of our robot through the Robot class. The call to `startup()` opens the serial ports to the various devices, loads the robot YAML parameters, and launches a few helper threads.

```python linenums="7"

for i in range(10):

@ -78,11 +76,11 @@ The call to `pretty_print()` prints to console all of the robot's sensor and sta

robot.stop()

```

Finally, the `stop()` method shuts down the Robot threads and cleanly closes the open serial ports.

Finally, the `stop()` method shuts down the threads and cleanly closes the open serial ports.

### Units

The Robot API uses SI units of:

The Robot API uses SI units:

* meters

* radians

@ -98,7 +96,7 @@ Parameters may be named with a suffix to help describe the unit type. For exampl

### The Robot Status

The Robot derives from the [Device class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/device.py). It also encapsulates a number of other Devices:

The Robot derives from the [Device class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/device.py). It also encapsulates several other Devices:

The Status dictionaries are automatically updated by a background thread of the Robot at around 25Hz. The Status data can be accessed via the Robot. For example:

The Status dictionaries are automatically updated by a background thread of the Robot class at around 25Hz. The Status data can be accessed via the Robot class as below:

```python

if robot.arm.status['pos']>0.25:

@ -129,8 +127,6 @@ If an instantaneous snapshot of the entire Robot Status is needed, the `get_stat

```python

status=robot.get_status()

if status['arm']['pos']>0.25:

print('Arm extension greater than 0.25m')

```

### The Robot Command

@ -169,18 +165,29 @@ The `move_by()` method queues up the command to the stepper motor controller. Ho

robot.push_command()

```

The `push_command()` causes all queued up commands to be executed at once. This allows for synchronization of motion across joints. For example, the following code will cause the base, arm, and lift to initiate motion simultaneously:

The `push_command()` causes all queued-up commands to be executed at once. This allows for the synchronization of motion across joints. For example, the following code will cause the base, arm, and lift to initiate motion simultaneously:

```python linenums="1"

import time

import stretch_body.robot

robot=stretch_body.robot.Robot()

robot.startup()

```python

robot.arm.move_by(0.1)

robot.lift.move_by(0.1)

robot.base.translate_by(0.1)

robot.push_command()

time.sleep(2.0)

robot.stop()

```

**NOTE**: In this example we call `sleep()` to allow time for the motion to complete before initiating a new motion.

!!! note

In this example we call `sleep()` to allow time for the motion to complete before initiating a new motion.

**NOTE**: The Dynamixel servos do not use the Hello Robot communication protocol. As such, the head, wrist, and gripper will move immediately upon issuing a motion command.

!!! note

The Dynamixel servos do not use the Hello Robot communication protocol. As such, the head, wrist, and gripper will move immediately upon issuing a motion command.

------

<divalign="center"> All materials are Copyright 2022 by Hello Robot Inc. Hello Robot and Stretch are registered trademarks.</div>

In this tutorial we will discuss how parameters are managed in Stretch Body and show examples of how to customize your robot by overriding parameters.

In this tutorial, we will discuss how parameters are managed in Stretch Body and show examples of how to customize your robot by overriding parameters.

## Overview

Stretch Body shares a global set of parameters across all of the hardware it manages. All members of the [Device class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/device.py) have an instance of [RobotParams](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_params.py). This class constructs a dictionary of the device parameters and well as the global parameters for each device. For example from iPython try:

Stretch Body shares a global set of parameters across all of the hardware it manages. All members of the [Device class](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/device.py) have an instance of [RobotParams](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/robot_params.py). This class constructs a dictionary of the device parameters as well as the global parameters for each device. For example, from iPython try:

```python

import stretch_body.arm

@ -31,7 +31,7 @@ Out[7]:

'range_m': [0.0, 0.52]}

```

Or to access another device params:

or to access another device params:

```python

a.robot_params['lift']

@ -64,10 +64,10 @@ Stretch Body utilizes a prioritized parameter organization such that default set

| 1 | user_params | $HELLO_FLEET_PATH/$HELLO_FLEET_ID/ stretch_user_params.yaml | Yaml file for users to override default settings and to define custom configurations. |

| 2 | configuration_params | $HELLO_FLEET_PATH/$HELLO_FLEET_ID/ stretch_configuration_params.yaml | Robot specific data (eg, serial numbers and calibrations). Calibration tools may update these. |

| 3 | external_params | Imported via a list defined as `params` in stretch_user_params.yaml | External Python parameter dictionaries for 3rd party devices and peripherals. |

| 4 | nominal_params | stretch_body.robot_params_RE2V0.py | Generic systems settings (Common across all robots of a given model. |

| 5 | nominal_system_params | stretch_body.robot_params.py | Generic systems settings (Common across all robots models). |

| 4 | nominal_params | stretch_body.robot_params_RE2V0.py | Generic systems settings (common across all robots of a given model. |

| 5 | nominal_system_params | stretch_body.robot_params.py | Generic systems settings (common across all robot models). |

This allows the user to override any of the parameters by defining it in their `stretch_user_params.yaml`. It also allows Hello Robot to periodically update parameters defined in the Python files via Pip upadates.

This allows the user to override any of the parameters by defining it in their `stretch_user_params.yaml`. It also allows Hello Robot to periodically update parameters defined in the Python files via Pip updates.

The tool `stretch_params.py` will print out all of the robot parameters as well as their origin. For example:

The factory parameter settings should suffice for most use cases.

!!! note

The factory parameter settings should suffice for most use cases.

## Programmatically Modifying and Storing Parameters

A user want to compute the value of a parameter programmatically and modify the robot settings accordingly. For example, in the Stretch Factory tool [REx_base_calibrate_wheel_seperation.py](https://github.com/hello-robot/stretch_factory/blob/master/python/tools/REx_base_calibrate_wheel_separation.py) we see that the parameter `wheel_seperation_m` is recomputed as the variable `d_avg`. This new value could be used during the robot execution by simply

A user can compute the value of a parameter programmatically and modify the robot settings accordingly. For example, in the Stretch Factory tool [REx_base_calibrate_wheel_seperation.py](https://github.com/hello-robot/stretch_factory/blob/master/python/tools/REx_base_calibrate_wheel_separation.py) we see that the parameter `wheel_seperation_m` is recomputed as the variable `d_avg`. This new value could be used during the robot execution by simply:

As we've seen in previous tutorials, commanding robot motion can be simple and straight forward. For example, incremental motion of the arm can be commanded by:

As we've seen in previous tutorials, commanding robot motion is simple and straightforward. For example, the incremental motion of the arm can be commanded by:

```python linenums="1"

import stretch_body.robot

@ -14,7 +14,7 @@ time.sleep(2.0)

robot.stop()

```

Or, absolute motion can be commanded by:

The absolute motion can be commanded by:

```python linenums="1"

import stretch_body.robot

@ -30,9 +30,7 @@ robot.stop()

## Waiting on Motion

In the above examples we execute a `time.sleep()` after `robot.push_command()`. This allows the joint time to complete its motion. Instead we can use the `wait_until_at_setpoint()` method that polls the joint position versus the target position. We can also interrupt a motion by sending a new motion command at anytime. For example, try the following script:

In the above examples, we executed a `time.sleep()` after `robot.push_command()`. This allows the joint time to complete its motion. As an alternative, we can use the `wait_until_at_setpoint()` method that polls the joint position versus the target position. We can also interrupt a motion by sending a new motion command at any time. For example, try the following script:

```python linenums="1"

import stretch_body.robot

@ -60,13 +58,13 @@ You will see the arm fully retract, begin to extend, and then fully retract agai

## Motion Profiles

All joints support [trapezoidal based motion](https://www.motioncontroltips.com/what-is-a-motion-profile/) generation. Other types of controllers are available (splined trajectory, PID, velocity, etc) but they are not covered here. The trapezoidal motion controllers require three values:

All joints support [trapezoidal motion profile](https://www.motioncontroltips.com/what-is-a-motion-profile/) generation. Other types of controllers are available (splined trajectory, PID, velocity, etc) but they are not covered here. The trapezoidal motion controllers require three values:

* x: target position of joint

* v: maximum velocity of motion

* a: acceleration of motion

We provide 'default' settings for the velocity and acceleration settings, as well as 'fast', and 'slow' settings. These values have been tuned to be appropriate for safe motion of the robot. These values can queried using the `stretch_params.py` tool:

We provide 'defaults' for the velocity and acceleration settings, as well as 'fast', and 'slow' settings. These values have been tuned to be appropriate for the safe movement of the robot. These values can be queried using the `stretch_params.py` tool:

```bash

>>$stretch_params.py | grep arm | grep motion | grep default

@ -98,7 +96,7 @@ All joints obey motion limits which are specified in the robot parameters.

These are the mechanical limits of the joint. These limits have been set at the factory to prevent damage to the hardware. It is not recommended to set them to be greater than the factoryspecified values. However, they can be further limited if desired by setting soft motion limits:

These are the mechanical limits of the joints and have been set at the factory to prevent damage to the hardware. It is not recommended to set them to be greater than the factory-specified values. However, they can be further limited if desired by setting soft motion limits:

The above examples have focused on the motion of the arm. Like the lift and the base, the arm utilizes Hello Robot's custom stepper motor controller. Control of the Dynamixels of the head and the end-of-arm is very similar to that of the arm (though not identical).

As we see here, the `robot.push_command` call is not required as the motion begins instantaneously and is not queued. In addition, the Dynamixel servos are managed as a chain of devices -- so we must pass in the joint name along with the command.

The above examples have focused on the motion of the arm. Like the lift and the base, the arm utilizes Hello Robot's custom stepper motor controller. Control of the Dynamixels of the head and the end-of-arm is very similar to that of the arm, though not identical.

As we see here, the `robot.push_command()` call is not required as the motion begins instantaneously and is not queued. In addition, the Dynamixel servos are managed as a chain of devices, so we must pass in the joint name along with the command.

```python

import stretch_body.robot

@ -151,7 +145,7 @@ time.sleep(3.0)

robot.stop()

```

Similarly to the stepper joints, the Dynamixel joints accept motion profile and motion limit commands. For example, here we restrict the head pan range of motion while executing both a fast and slow move:

Similar to the stepper joints, the Dynamixel joints accept motion profile and motion limit commands. For example, here we restrict the head pan range of motion while executing both a fast and slow move:

```python

import stretch_body.robot

@ -179,11 +173,9 @@ time.sleep(3.0)

robot.stop()

```

## Base Velocity Control

The Base also supports a velocity control mode which can be useful for use with navigation planner. The Base controllers will automatically switch between velocity and position based control. For example:

The Base also supports a velocity control mode which can be useful with navigation planners. The Base controllers will automatically switch between velocity and position control. For example:

As shown, care should be taken to set commanded velocities to zero on exit to avoid runaway.

!!! warning

As shown, care should be taken to set commanded velocities to zero on exit to avoid runaway.

## Advanced Topics

### Stepper Control Modes

Most users will control robot motion using the `move_to` and `move_by` commands as described above. There are numerous other low-level controller modes available. While these are a topic for advanced users, it is worth noting that each joint has a default safety mode and a default position control mode. These are:

Most users will control robot motion using the `move_to` and `move_by` commands as described above. However, there are numerous other low-level controller modes available. While this is a topic for advanced users, it is worth noting that each joint has a default safety mode and a default position control mode. These are:

| Joint | Default Safety Mode | Default Position Control Mode |

@ -217,11 +209,11 @@ Most users will control robot motion using the `move_to` and `move_by` commands

| wrist_yaw | Torque disabled | Trapezoidal position control |

| stretch_gripper | Torque disabled | Trapezoidal position control |

Each joint remains in Safety Mode when no program is running. When the `<device>.startup()` function is called, the joint controller transitions from Safety Mode to its Default Position Control Mode. It is then placed back in Safety Mode when `<device>.stop()` is called.

Each joint remains in its `Safety Mode` when no program is running. When the `<device>.startup()` function is called, the joint controller transitions from `Safety Mode` to its `Default Position Control Mode`. It is then placed back in `Safety Mode` when `<device>.stop()` is called.

### Motion Runstop

Runstop activation will cause the Base, Arm, and Lift to switch to Safety Mode and for subsequent motion commands will be ignored. The motion commands will resume smoothly when the runstop is deactivated. This is usually done via the runstop button. However, it can also be done via the Pimu interface. For example:

Runstop activation will cause the Base, Arm, and Lift to switch to `Safety Mode` and subsequent motion commands will be ignored. The motion commands will resume smoothly when the Runstop is deactivated. This is usually done via the Runstop button. However, it can also be done via the Pimu interface. For example:

The Arm, Lift, and Base support a guarded motion function. It will automatically transition the actuator from Control mode to Safety mode when the exerted motor torque exceeds a threshold.

The Arm, Lift, and Base support a guarded motion function. It will automatically transition the actuator from Control mode to Safety mode when the exerted motor torque exceeds a threshold.

This functionality is most useful for the Lift and the Arm. It allows these joints to safely stop upon contact. It can be used to:

* Safely stop when contacting an actuator hardstop

* Safely stop when contacting an actuator hardstop

* Safely stop when making unexpected contact with the environment or a person

* Make a guarded motion where the robot reaches to a surface and then stops

* Make a guarded motion where the robot reaches a surface and then stops

For more information on guarded motion, see the [Contact Models Tutorial](./tutorial_contact_models.md)

It can be useful to poll the status of a joint during motion in order to modify the robot behavior, etc. The useful status values include:

It can be useful to poll the status of a joint during a motion to modify the robot's behavior, etc. The useful status values include:

```python

robot.arm.status['pos'] #Joint position

@ -306,11 +295,14 @@ The following update rates apply to Stretch:

| Command data for Arm, Lift, Base, Wacc, Pimu | N/A | Commands are queued and executed upon calling robot.push_command( ) |

| Command data for End of Arm and Head servos | N/A | Commands execute immediately |

Motion commands are non-blocking and it is the responsibility of the user code to poll the Robot Status to determine when and if a motion target has been achieved.

!!! note

Motion commands are non-blocking and it is the responsibility of the user code to poll the Robot Status to determine when and if a motion target has been achieved.

The Stretch_Body interface is not designed to support high bandwidth control applications. The natural dynamics of the robot actuators do not support high bandwidth control, and the USB based interface limits high rate communication.

!!! info

The Stretch Body interface is not designed to support high bandwidth control applications. The natural dynamics of the robot actuators do not support high bandwidth control, and the USB-based interface limits high-rate communication.

In practice, a Python based control loop that calls push_command( ) at 1Hz to 10Hz is sufficiently matched to the robot natural dynamics.

!!! tip

In practice, a Python-based control loop that calls push_command() at 1Hz to 10Hz is sufficiently matched to the robot's natural dynamics.

------

<divalign="center"> All materials are Copyright 2022 by Hello Robot Inc. Hello Robot and Stretch are registered trademarks.</div>

Stretch Body exposes a host of sensor data through the status dictionaries of its devices. In this tutorial we'll cover how to access, view, and configure this sensor data.

Stretch Body exposes a host of sensor data through the status dictionaries of its devices. In this tutorial, we'll cover how to access, view, and configure this sensor data.

## Tools to View Sensor Data

There are two useful tools for scoping Pimu and Wacc sensor data in real-time:

There are two useful tools for scoping Pimu and Wacc sensor data in real-time:

The base has a 9 DOF IMU using the 9 DOF FXOS8700 + FXAS21002 chipset. This is the same chipset as used on the [Adafruit NXP IMU board](https://www.adafruit.com/product/3463).

The base has a 9-DoF IMU using the 9-DoF FXOS8700 + FXAS21002 chipset. This is the same chipset used on the [Adafruit NXP IMU board](https://www.adafruit.com/product/3463).

The [Pimu](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/pimu.py) reports back the IMU sensor readings in its [IMU status dictionary](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/pimu.py#L27). For example, from iPython try:

@ -200,7 +200,7 @@ It reports:

These values are computed on the Pimu. As we can see in [its firmware code](https://github.com/hello-robot/stretch_firmware/blob/master/arduino/hello_pimu/IMU.cpp), a 100Hz Madgwick filter is used to compute the orientation.

Stretch Body also implements a bump detector using the the IMU accelerometers. This detector simply [computes the sum-of-squares of AX, AY, and AZ](https://github.com/hello-robot/stretch_firmware/blob/master/arduino/hello_pimu/IMU.cpp#L223). This value is then compared to the following threshold to determine if a bump is present:

Stretch Body also implements a bump detector using the IMU accelerometers. This detector simply [computes the sum of squares of AX, AY, and AZ](https://github.com/hello-robot/stretch_firmware/blob/master/arduino/hello_pimu/IMU.cpp#L223). This value is then compared to the following threshold to determine if a bump is detected:

**NOTE**: The IMU is calibrated by Hello Robot at the factory. Please contact Hello Robot support for details on recalibrating your IMU.

!!! note

The IMU is calibrated by Hello Robot at the factory. Please contact Hello Robot support for details on recalibrating your IMU.

## Wrist Accelerometer

The wrist includes a 3 axis [ADXL343](https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL343.pdf) accelerometer which provides bump and tap detection capabilities. The Wacc reports back AX, AY, and AZ [in its status dictionary](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/wacc.py#L44) From iPython try:

The wrist includes a 3 axis [ADXL343](https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL343.pdf) accelerometer which provides bump and tap detection capabilities. The Wacc reports back AX, AY, and AZ [in its status dictionary](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/wacc.py#L44). For example, from iPython try:

In addition to AX, AY, and AZ we also see the `single_tap_count` value which reports back a count of the number of single-tap contacts the accelerometer has experiences since power-up.

In addition to AX, AY, and AZ we also see the `single_tap_count` value which reports back a count of the number of single-tap contacts the accelerometer has experienced since power-up.

The following Wacc parameters configure the accelerometer low-pass filter and single-tap settings. See the [ADXL343](https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL343.pdf) datasheet for more details.

The following Wacc parameters configure the accelerometer low-pass filter and single-tap settings. See the [ADXL343](https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL343.pdf) datasheet for more details.

Stretch has four Sharp GP2Y0A51SK0F IR cliff sensors pointed towards the floor. These report the distance to the floor, allowing for detection of thresholds, stair edges, etc.

Stretch has four Sharp GP2Y0A51SK0F IR cliff sensors pointed toward the floor. These report the distance to the floor, allowing for the detection of thresholds, stair edges, etc.

Relevant parameters for the cliff sensors are:

@ -325,9 +324,10 @@ Calibration passed. Storing to YAML...

The `stop_at_cliff` field causes the robot to execute a Runstop when the cliff sensor readings exceed the value `cliff_thresh`. The parameter `cliff_LPF` defines the low-pass-filter rate (Hz) on the analog sensor readings.

**Note: As configured at the factory, `stop_at_cliff` is set to zero and Stretch does not stop its motion based on the cliff sensor readings. Hello Robot makes no guarantees as to the reliability of Stretch's ability to avoid driving over ledges and stairs when this flag is enabled.**

!!! note

As configured at the factory, `stop_at_cliff` is set to zero and Stretch does not stop its motion based on the cliff sensor readings. Hello Robot makes no guarantees as to the reliability of Stretch's ability to avoid driving over ledges and stairs when this flag is enabled.

The range values from the sensors can be read from the `robot.pimu.status` message. Relevant fields are:

The range values from the sensors can be read from the `robot.pimu.status` message. The relevant fields are:

```python

import stretch_body.robot

@ -345,7 +345,7 @@ Out[5]: False

```

The `cliff_event` flag is set when any of the four sensor readings exceed `cliff_thresh` and `stop_at_cliff` is enabled. In the event of a Cliff Event, it must be reset by `robot.pimu.cliff_event_reset()`in order to reset the generated Runstop.

The `cliff_event` flag is set when any of the four sensor readings exceed `cliff_thresh` and `stop_at_cliff` is enabled. In the event of a Cliff Event, it must be reset by `robot.pimu.cliff_event_reset()` to reset the generated Runstop.

The cliff detection logic can be found in the [Pimu firmware](https://github.com/hello-robot/stretch_firmware/blob/master/arduino/hello_pimu/Pimu.cpp).

Stretch includes a number of built-in functions that help it maintain safe operating conditions. These functions can be disabled and enabled via the robot user parameters.

Stretch includes several built-in functions that help it maintain safe operating conditions. These functions can be disabled and enabled via the robot user parameters.

## Logging

@ -15,7 +15,7 @@ robot:

## Runstop Functions

The runstop deactivates all robot motion. It can be triggered by the physical button on the robot's head. It can also be triggered by internal monitors of the system state. The default configuration of these parameters is:

The Runstop deactivates all robot motion. It can be triggered by the physical button on the robot's head. It can also be triggered by internal monitors of the system state. The default configuration of these parameters is:

The [Pimu firmware](https://github.com/hello-robot/stretch_firmware/tree/master/arduino/hello_pimu) details the implementation of these functions.

**NOTE**: The `stop_at_cliff` and `stop_at_tilt` functions are disabled by default as they are not robust to normal operating conditions of the robot. Therefore do not rely on these functions for robot safety.

!!! warning

The `stop_at_cliff` and `stop_at_tilt` functions are disabled by default as they are not robust to the normal operating conditions of the robot. Therefore do not rely on these functions for robot safety.

## Robot Monitor

The [Robot Monitor](https://github.com/hello-robot/stretch_body/blob/master/python/stretch_body/robot_monitor.py) is a thread that monitors the Robot Status data for significant events. For example, it can monitor the error flags from the Dynamixel servos and notify when a thermal overload occurs. The Robot Monitor logs warnings to a log file by default. T

The [Robot Monitor](https://github.com/hello-robot/stretch_body/blob/master/python/stretch_body/robot_monitor.py) is a thread that monitors the Robot Status data for significant events. For example, it can monitor the error flags from the Dynamixel servos and notify when a thermal overload occurs. The Robot Monitor logs warnings to a log file by default.

The default parameters associated with RobotMonitor are:

@ -78,7 +79,7 @@ robot:

log_to_console: 1

```

The run the tool and hit the runstop button, then hold it down for 2 seconds:

Then run the tool and hit the Runstop button, and then hold it down for 2 seconds:

```bash

>>$ stretch_robot_monitor.py

@ -91,11 +92,9 @@ Starting Robot Monitor. Ctrl-C to exit

[INFO] [robot_monitor]: Runstop deactivated

```

## Robot Sentry

The [Robot Sentry](https://github.com/hello-robot/stretch_body/blob/master/python/stretch_body/robot_sentry.py) is a thread that can override and also generate commands to the robot hardware. It's purpose is to keep the robot operating within a safe regime. For example, the Robot Sentry monitors the position of the Lift and Arm and limits the maximum base velocity and acceleration (in order to reduce the chance of toppling). The Robot Sentry reports events to the log file as well.

The [Robot Sentry](https://github.com/hello-robot/stretch_body/blob/master/python/stretch_body/robot_sentry.py) is a thread that can override and also generate commands to the robot hardware. Its purpose is to keep the robot operating within a safe regime. For example, the Robot Sentry monitors the position of the Lift and Arm and limits the maximum base velocity and acceleration to reduce the chance of toppling. The Robot Sentry reports events to the log file as well.

@ -4,12 +4,11 @@ Stretch Body supports splined trajectory controllers across all of its joints. T

## What are Splined Trajectories?

A splined trajectory is a smooth path that a robot joint follows over a specific period of time. [Cubic or quintic splines](https://en.wikipedia.org/wiki/Spline_(mathematics)) are used to represent the trajectory. As shown below, the splines (blue) are defined by a series of userprovided waypoints (black dot). A waypoint is simply a target position, velocity, and optional acceleration at a given time. The spline ensures continuity and smoothness when interpolating between the waypoint targets.

A splined trajectory is a smooth path that a robot joint follows over a specific period of time. [Cubic or quintic splines](https://en.wikipedia.org/wiki/Spline_(mathematics)) are used to represent the trajectory. As shown below, the splines (blue) are defined by a series of user-provided waypoints (black dot). A waypoint is simply a target position, velocity, and optional acceleration at a given time. The spline ensures continuity and smoothness when interpolating between the waypoint targets.

During execution, the trajectory controller uses this splined representation to compute the instantaneous desired position, velocity, and acceleration of the joint (red). On Stretch, this instantaneous target is then passed to a lower-level position or velocity controller.

Splined trajectories are particularly useful when you want to coordinate motion across several joints. Because the trajectory representation is time based, it is straightforward to encode multi-joint coordination. Stretch Body supports both cubic and quintic spline. A quintic spline waypoint includes acceleration in the waypoint target, while a cubic spline does not.

Splined trajectories are particularly useful when you want to coordinate motion across several joints. Because the trajectory representation is time-based, it is straightforward to encode multi-joint coordination. Stretch Body supports both cubic and quintic splines. A quintic spline waypoint includes acceleration in the waypoint target, while a cubic spline does not.

@ -44,7 +43,8 @@ The tool GUI allows you to interactively construct a splined trajectory and then

**NOTE**: Use caution when commanding the base. Ensure that attached cables are long enough to support base motion. Alternatively you may want to put the base on top of a book so the wheel don't touch the ground.

!!! note

Use caution when commanding the base. Ensure that the attached cables are long enough to support the base motion. Alternatively, you may want to put the base on top of a book so the wheels don't touch the ground.

Finally, you can explore a full-body trajectory using the non-GUI version of the tool:

@ -52,11 +52,9 @@ Finally, you can explore a full-body trajectory using the non-GUI version of the

>>$ stretch_trajectory_jog.py --full_body

```

## Programming Trajectories

Programming a splined trajectory is straightforward. Try the following from iPython:

Programming a splined trajectory is straightforward. For example, try the following from iPython:

```python

import stretch_body.robot

@ -88,22 +86,21 @@ This will cause the arm to move from its current position to 0.45m, then back to

* This will execute a Cubic spline as we did not pass in accelerations to in `r.arm.trajectory.add`

* The call to `r.arm.follow_trajectory` is non-blocking and the trajectory generation is handled by a background thread of the Robot class

If you're interested in exploring the trajectory API further the [code for the `stretch_trajectory_jog.py`](https://github.com/hello-robot/stretch_body/blob/master/tools/bin/stretch_trajectory_jog.py)is a great reference to get started.

If you're interested in exploring the trajectory API further the [code for the `stretch_trajectory_jog.py`](https://github.com/hello-robot/stretch_body/blob/master/tools/bin/stretch_trajectory_jog.py)is a great reference to get started.

## Advanced: Controller Parameters

Sometimes the robot motion isn't quite what is expected when executing a splined trajectories. It is important that the trajectory be well-formed, meaning that it:

Sometimes the robot's motion isn't quite what is expected when executing a splined trajectory. It is important that the trajectory be well-formed, meaning that it:

* Respects the maximum velocity and accelerations limits of the joint

* Doesn't create a large 'excursion' outside of the acceptable range of motion in order to hit a target waypoint

* Doesn't create a large 'excursion' outside of the acceptable range of motion to hit a target waypoint

* Doesn't have waypoints so closely spaced together that it exceeds the nominal control rates of Stretch (~10-20 Hz)

For example, the arm trajectory below has a large excursion outside of the joints range of motion (white). This is because the second waypoint expects a non-zero velocity when the arm reaches full extension.

For example, the arm trajectory below has a large excursion outside of the joint's range of motion (white). This is because the second waypoint expects a non-zero velocity when the arm reaches full extension.

Often the trajectory waypoints will be generated from a motion planner. It is important that this planner incorporates the position, velocity, and acceleration constraints of the joint. These can be found by, for example

Often the trajectory waypoints will be generated from a motion planner. It is important for the planner to incorporate the position, velocity, and acceleration constraints of the joint. These can be found by, for example:

Fortunately the Stretch Body [Trajectory](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/trajectories.py) classes do some preliminary feasibility checking of trajectories using the [is_segment_feasible function](https://github.com/hello-robot/stretch_body/blob/master/body/stretch_body/hello_utils.py#L290). This checks if the generated motions lie within the constraints of the `trajectory_max` parameters.